The Rise of the 3D Printing Factory: A Revolution in Manufacturing

The advent of 3D printing technology has sparked a revolution across multiple industries, reshaping traditional manufacturing norms. A 3D printing factory stands at the forefront of this transformation, enabling businesses to innovate, reduce costs, and increase efficiency. In this comprehensive article, we will delve into the intricacies of 3D printing factories, exploring their applications, benefits, and future prospects in the business landscape.

Understanding 3D Printing Technology

Before we explore the impact of a 3D printing factory, it’s essential to understand what 3D printing actually is. In essence, 3D printing, also known as additive manufacturing, is a process that creates a physical object from a digital file. It involves laying down successive layers of material until the desired object is created.

The Process of 3D Printing

The 3D printing process typically follows these steps:

- Design: The first step involves creating a digital 3D model using computer-aided design (CAD) software.

- Conversion: The CAD file is converted into a format that the 3D printer can interpret, commonly STL or OBJ.

- Slicing: The file is then sliced into thin horizontal layers, which guides the printer on where to deposit material.

- Printing: The printer deposits successive layers of material, adhering to the previous layer until the object is completed.

- Post-Processing: After printing, the object may require finishing touches, such as sanding or painting, to achieve the desired surface quality.

Applications of 3D Printing Factories

A 3D printing factory is not limited to merely creating prototypes; it has extensive applications across various industries. Here are some notable sectors benefiting from this technology:

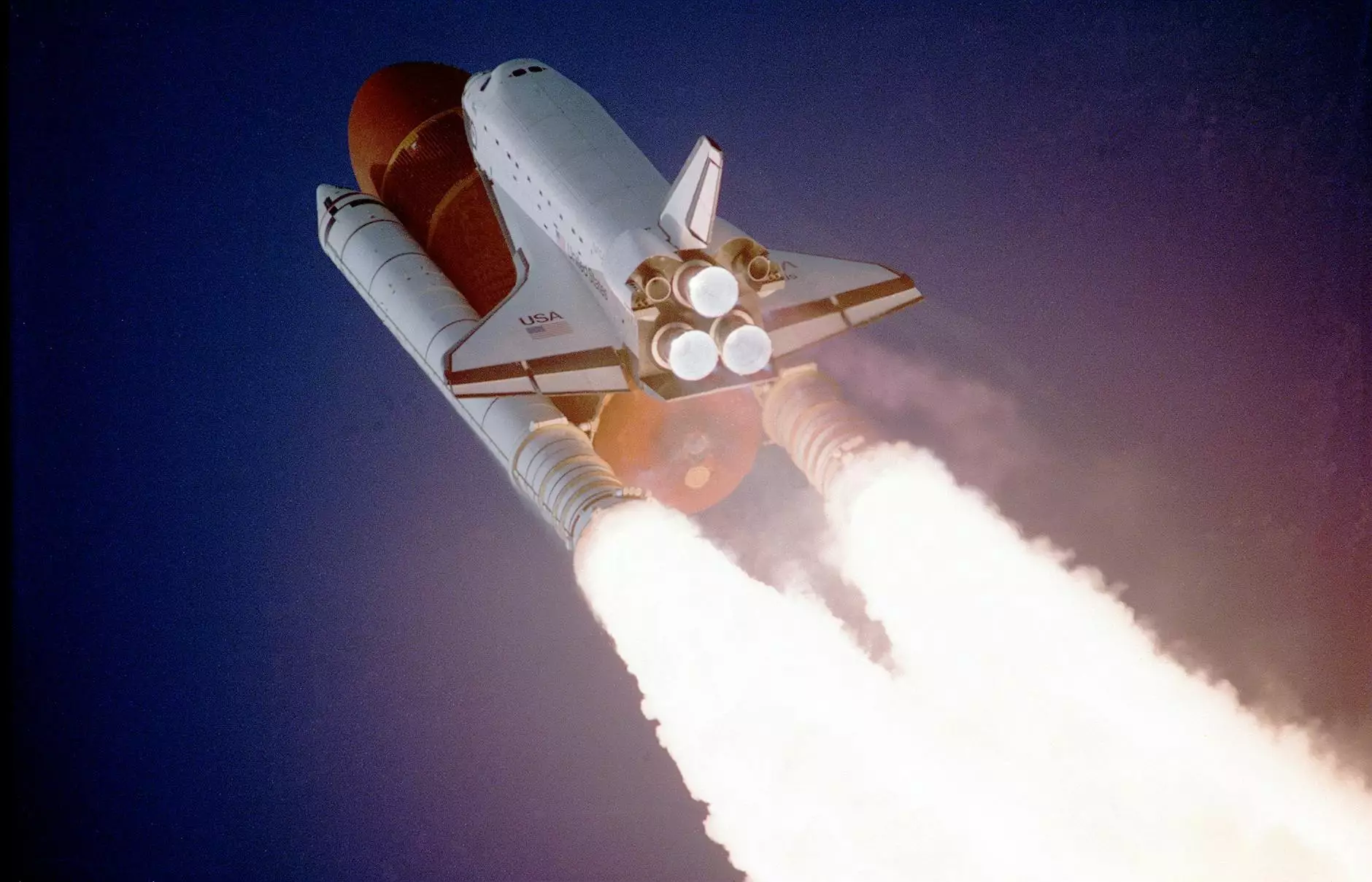

1. Aerospace and Aviation

The aerospace industry has embraced 3D printing for producing lightweight parts that can withstand extreme conditions. Components such as fuel nozzles and brackets are manufactured more efficiently, leading to lighter aircraft and reduced fuel costs.

2. Healthcare

Healthcare is one of the most prominent sectors utilizing 3D printing. Customized prosthetics, dental implants, and even bioprinted tissues are being produced, offering personalized solutions to patients and enhancing the quality of medical care.

3. Automotive

In the automotive industry, a 3D printing factory can produce complex designs quickly and cost-effectively. Manufacturers are using 3D printing for creating prototypes, end-use parts, and tooling, significantly speeding up the development process.

4. Fashion and Art

Fashion designers are harnessing 3D printing to create innovative garments and accessories. This technology allows for intricate designs that were previously unachievable through traditional manufacturing methods.

5. Construction

The construction sector is also exploring 3D printing, with techniques being developed to print entire structures. This innovation promises to reduce construction times and costs significantly while also addressing labor shortages in the industry.

Benefits of a 3D Printing Factory

The advantages of implementing a 3D printing factory in business operations are profound and varied. Here’s a closer look at the benefits:

1. Cost Efficiency

3D printing minimizes material waste compared to traditional manufacturing techniques, resulting in significant cost savings. Additionally, the ability to print on-demand reduces inventory costs.

2. Customization

One of the leading advantages of 3D printing is the ability to create customized products tailored to individual client specifications. This is particularly valuable in sectors like healthcare and fashion.

3. Rapid Prototyping

3D printing allows businesses to produce prototypes quickly. This rapid prototyping accelerates product development cycles, enabling companies to bring their products to market faster than before.

4. Complex Geometries

3D printing facilitates the creation of complex geometries that would be impossible or too expensive to produce with traditional methods. This capability opens new design possibilities for engineers and designers alike.

5. Reduced Labor Costs

With automation at the heart of 3D printing processes, there is a potential for reduced labor costs. Fewer hands are needed to operate machines, allowing businesses to focus their workforce on other vital areas.

The Future of 3D Printing Factories

As we look to the future, the impact of 3D printing factories is expected to expand. Technological advances will continue to enhance printing capabilities, materials, and techniques.

1. Material Innovations

One of the significant focuses for the future is the development of new materials that can be used for 3D printing. Innovations in polymers, metals, and even bio-materials will broaden the applications and strengthen the durability of printed products.

2. Sustainability

In an era where sustainability is paramount, 3D printing offers potential solutions. Factories using eco-friendly materials and processes can significantly reduce their environmental impact.

3. Integration with AI

The integration of artificial intelligence (AI) with 3D printing technology can optimize design processes, enhance predictive maintenance, and streamline production workflows.

4. Decentralized Manufacturing

3D printing paves the way for decentralized manufacturing systems. This trend allows local production, reducing transportation costs and the carbon footprint associated with shipping products globally.

Challenges Facing 3D Printing Factories

While the benefits of 3D printing technology are compelling, some challenges need addressing:

1. Intellectual Property Concerns

The ease of copying designs in the digital realm raises significant intellectual property issues. Protecting designs and ensuring legitimate use of the technology is a growing concern.

2. Quality Control

Ensuring the quality and consistency of printed products remains a challenge. Development of standardization and regulations will be crucial as the industry matures.

3. Initial Setup Costs

While operational costs can decrease over time, the initial investment for 3D printing equipment and technology can be considerable, particularly for small businesses.

Conclusion

The emergence of 3D printing factories represents a paradigm shift in manufacturing, offering limitless possibilities and advantages that extend across numerous industries. From customized healthcare solutions to innovative product designs in fashion and automotive sectors, the impact of this technology is vast and profound. As challenges are addressed and technological advancements continue, the potential for 3D printing factories to revolutionize how we design, produce, and interact with manufactured goods is not merely a promise—it's an impending reality.

As a business owner exploring Art Supplies, Product Design, and 3D Printing, a deep understanding of the capabilities and advantages offered by 3D printing factories will be essential for maintaining a competitive edge in this swiftly evolving landscape. The future is bright for businesses willing to adapt and innovate through the power of 3D printing technology.